Introduction

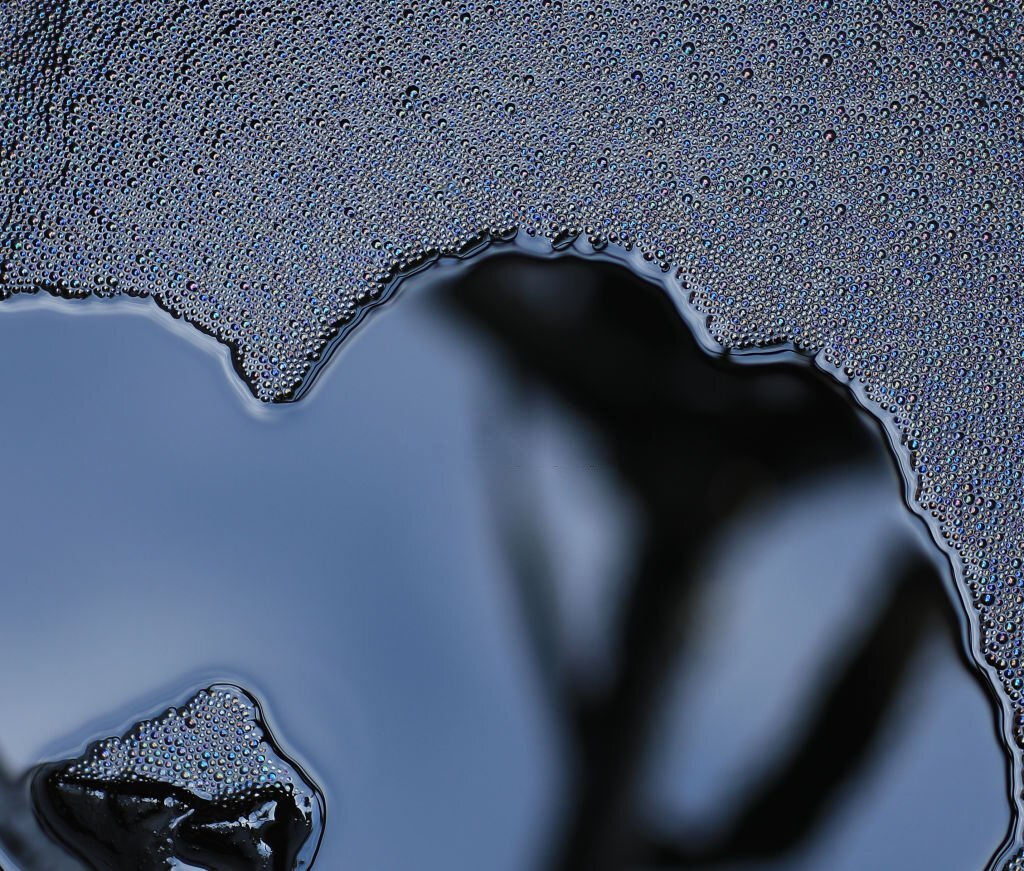

The client is a market leader in the value-added bitumen segment, with eight advanced manufacturing plants across India and a marketing network that services road construction activity across India.

Over the years, the client has played a pioneering role in the evolution of Bitumen Emulsions and Modified Bitumen as technologically superior alternatives for specific applications in the road construction industry in India.

Challenges

The client was using the traditional method for managing the quality at Bitumen Emulsions. The traditional method had many limitations as far as delivering accurate results w.r.t. Particle details in Bitumen were concerned. It was proving to be a big failure. Moreover, the data acquired was not sufficient to control the quality of the final product or even for process improvement.

The client was in search of a product that will deliver accurate results pertaining to particle details to ensure the precise control over quality in Bitumen Emulsions.

Solution

The client summoned ImageProVision to take charge of the situation and address the challenges in the best possible way. The IPV experts enlightened the client about how particle size analysis can be done for Bitumen Emulsions with microscopy to arrive at accurate results and to have better quality control. It was decided that ipvPSA with little customization needs to be implemented.

During the implementation phase, it was observed that the Bitumen’s attribute of being opaque created hurdles in capturing images through a microscope. In addition, to create the sample, special solutions were needed that would provide particle details.

The IPV experts created a totally new and simple preparation method for the client. With the ipvPSA installed, the client could easily separate isolated particles and agglomerations. The newly developed particle identification algorithms enabled the client with wide-ranging parameters and particle images with greater accuracy. Besides creating manual options for user-specific inputs, IPV experts also developed customizable reports.

Benefits

→ A new, easy and quick method for checking the quality of Bitumen Emulsions

→ Statistical data not only helped quality control but also process improvement thus cutting greatly on time and effort

→ Exposure to a new & advanced measuring technology

→ Online support and frequent on-site visits helped manage all the hurdles related to execution