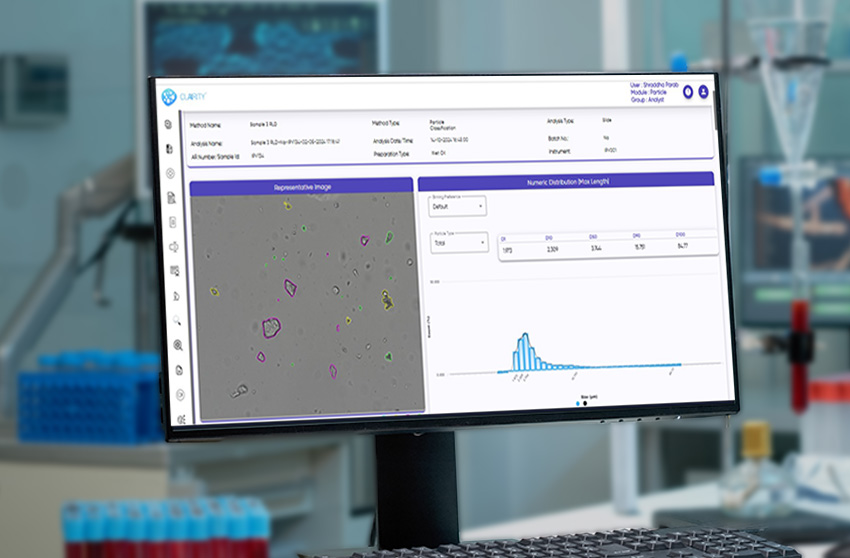

Static Image analysis.

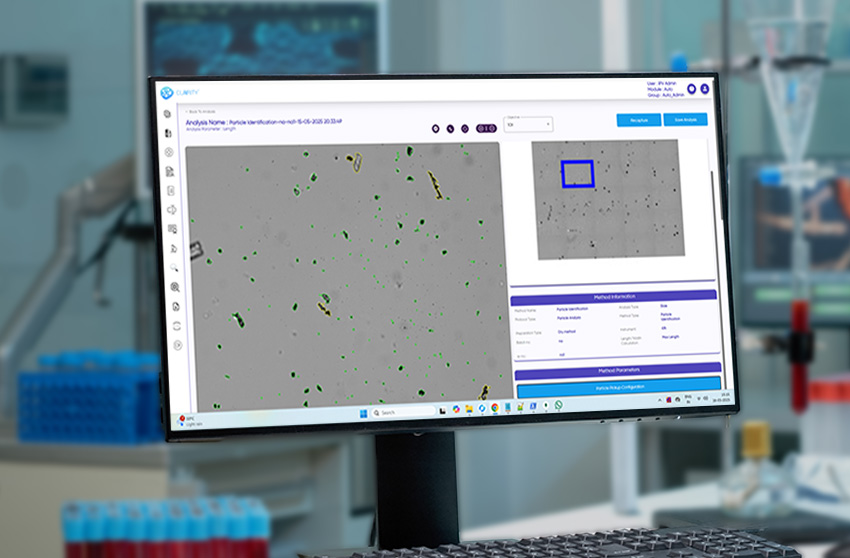

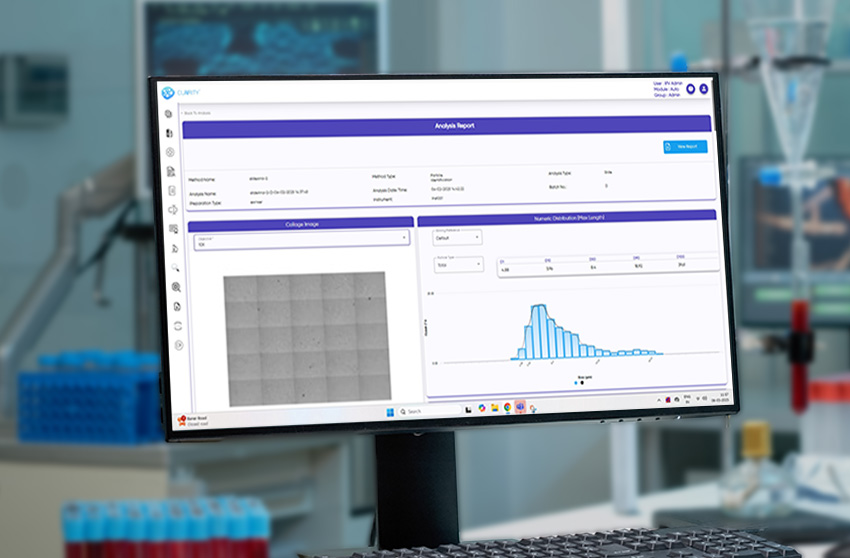

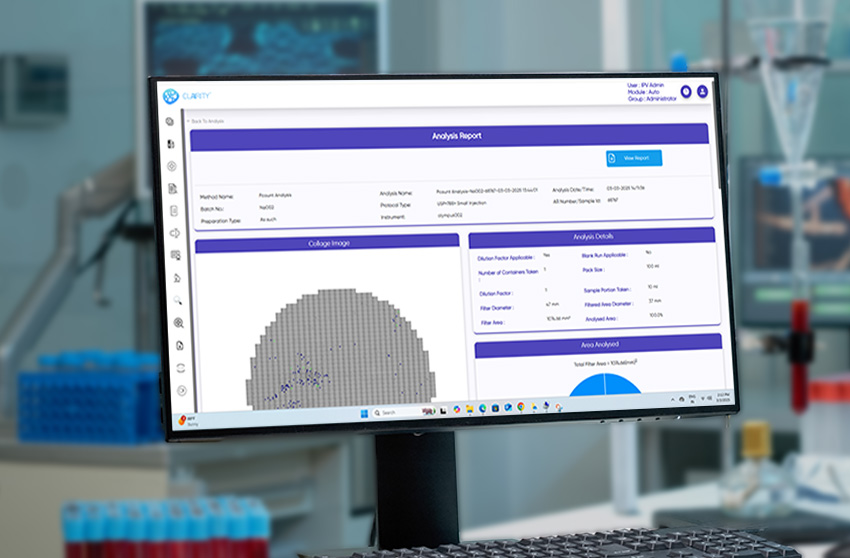

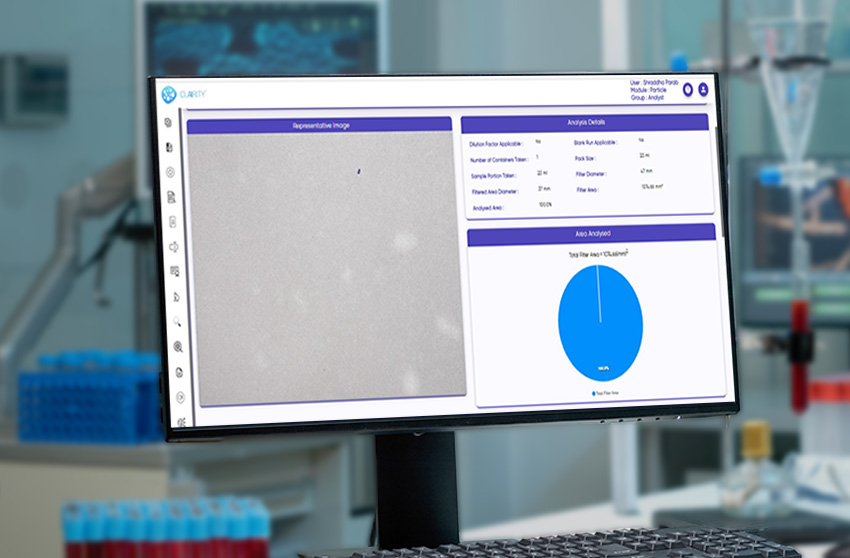

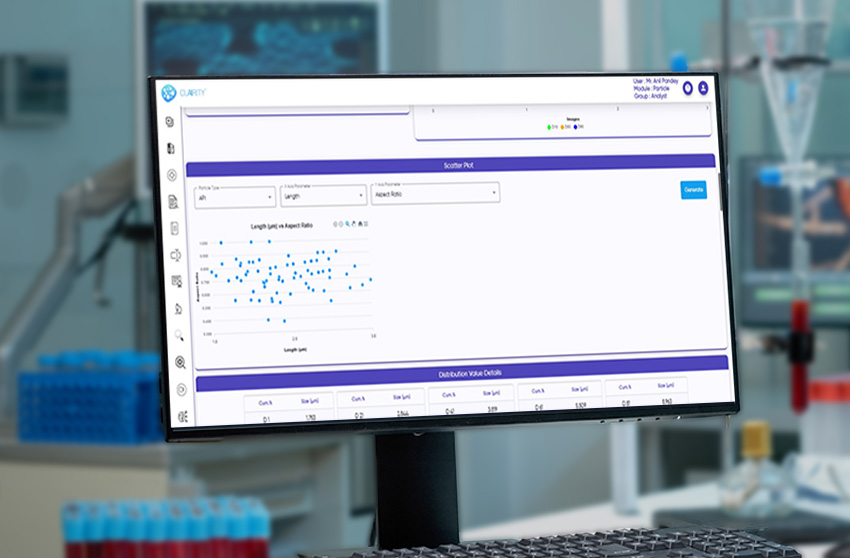

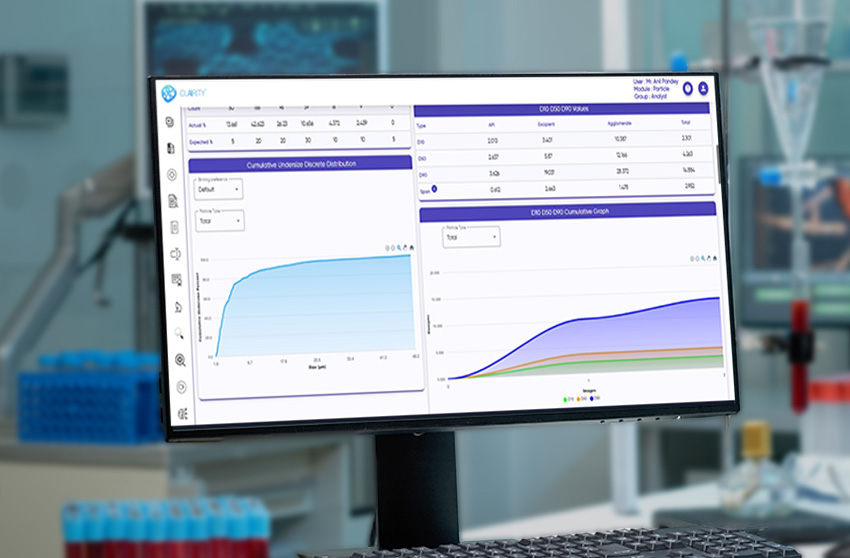

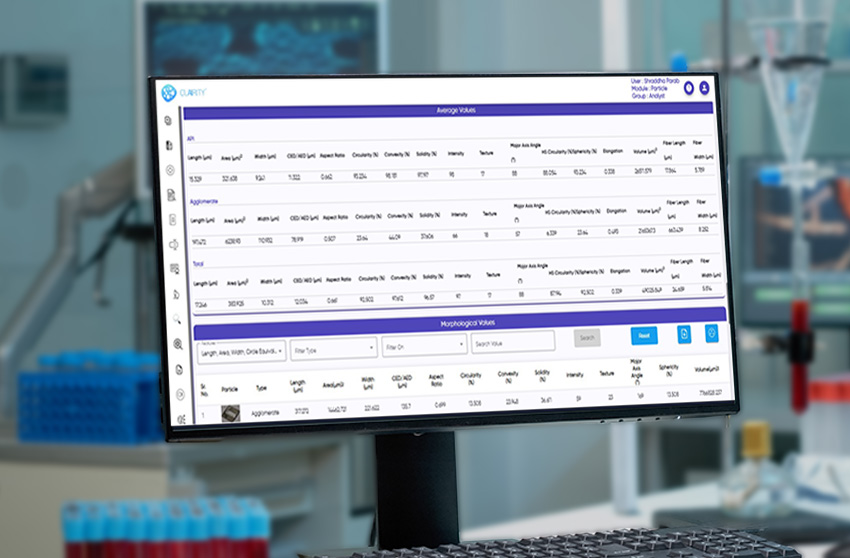

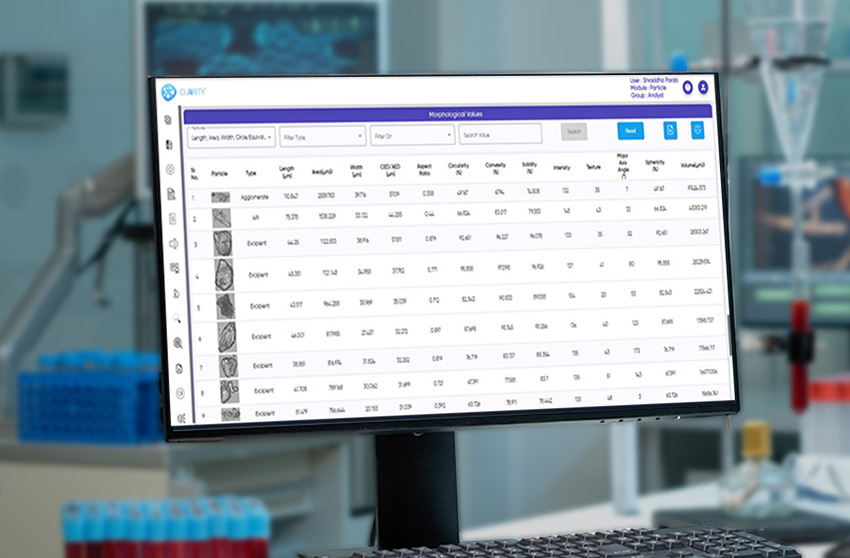

Particle characterization plays a foundational role in developing and manufacturing pharmaceutical products. Precise particle size and morphology measurement is essential to maintain quality, ensure processability, and confirm product efficacy. CLAIRITY™ SIA builds on the principles of static image analysis, a leading technology platform for capturing detailed particle insights, non-destructively and with high analytical clarity.

Using high-resolution imaging from SEM and optical sources, the system extracts accurate data on particle size, shape, and texture across dispersed powders, suspensions, emulsions, and solutions—whether on glass slides, filter paper, or within intact sample cells. CLAIRITY SIA combines the performance of Olympus microscopy with the sensitivity of the CLAIRITY™ Particle Analysis Suite, delivering a high-performance solution for regulated and research-driven environments.