- Why particle size matters

- AI in pharma and bio industry

- Particle characterization

- Where the industry is headed

- Why is particle shape important

- Effects of particle shape and size on drug delivery systems

- Dissolution parametric

- Particle analysis description

Why particle size matters

Why particle size matters

In any formulation or process, the size of individual particles is more than a technical detail—it influences how materials behave, interact, and perform. Whether you’re dealing with fluid flow in energy systems or dissolution rates in pharmaceuticals, particle size directly shapes efficiency, reliability, and end-product quality.

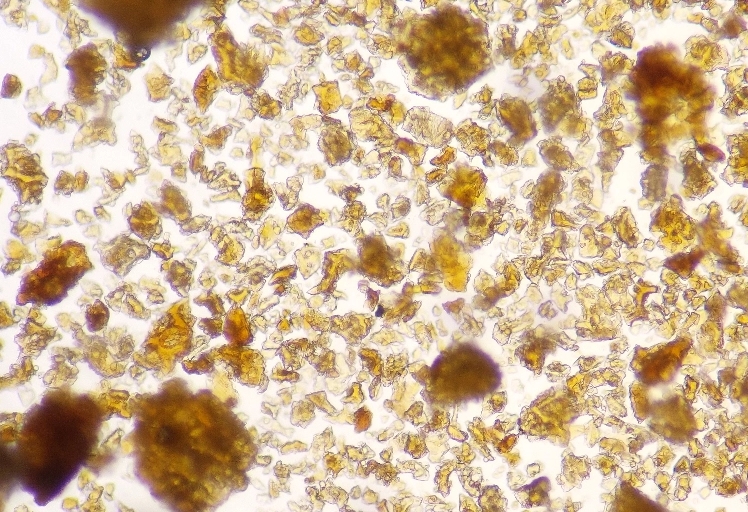

Microscopy plays a central role here. Unlike bulk techniques, it offers a direct visual estimate of particle size by capturing two-dimensional images for analysis. Measurements are drawn by comparing each particle’s projected area against calibrated reference scales, such as graticules, making it possible to build a reliable size distribution profile—especially within the 0.8–150 µm range, or even lower with electron microscopy.

But capturing the right data takes more than just magnification. Sampling needs to be precise and representative. Manual analysis, though still used, is prone to fatigue and variation. That’s where semi-automated systems step in—speeding up evaluations and minimizing human error, while still retaining the analytical rigor microscopy demands.

Ultimately, understanding particle size isn’t about compliance checklists or theoretical precision—it’s about knowing how to stabilize your processes, improve consistency, and detect variation before it turns into deviation.

AI in pharma and bio industry

AI in pharma and bio industry

AI and machine learning are reimagining how particle systems are studied, interpreted, and optimized. In pharmaceutical and biotechnological settings, they bring speed, accuracy, and depth to every stage of particle characterization.

- Image analysis is now automated. ML algorithms trained on microscopy datasets can identify and classify particles based on size, shape, texture, and color, delivering results faster and with fewer errors than manual methods.

- Particle tracking has moved from manual observation to real-time analytics. AI models help monitor particle motion and interaction, generating insights on velocity, diffusion, and behavior under variable conditions.

- Feature extraction from particle data is a more nuanced process. ML tools capture morphological and statistical markers—such as fractal dimensions or texture metrics—enabling deeper categorization and material prediction.

- Data analysis and modeling benefit from pattern recognition that scales. ML surfaces relationships across large datasets, detecting correlations that conventional analysis might miss. This improves decision-making in both R&D and manufacturing.

- Simulation support is stronger with AI-informed calibration. Models learn from laboratory results to enhance predictive accuracy, thereby optimizing formulations and predicting behavior across various scenarios.

Real-time decision systems now run on intelligent feedback loops. AI tools continuously analyze live particle data to support quality control and spot deviations early, reducing batch failures and improving yield.

Particle characterization

Particle characterization

Particle characterization helps decode how a material behaves by measuring its size, shape, composition, surface features, and concentration. These parameters influence everything from drug release and flow to chemical stability and process efficiency.

- Size affects dissolution, dispersion, and absorption. Techniques include microscopy, laser diffraction, and DLS.

- Shape alters flow, compressibility, and surface contact. Microscopy and automated image analysis detect variations.

- Composition reveals chemical identity through spectroscopy or elemental analysis.

- Surface properties like porosity, charge, and wettability determine interaction and retention. These are assessed using BET analysis, contact angle tests, or zeta potential.

- Concentration helps track uniformity and dosage using particle counters or flow cytometry.

Where the industry is headed

Where the industry is headed

AI and machine learning are redefining particle characterization—moving it from static measurement to dynamic, insight-led action.

Process control is becoming continuous. Machine learning models now interpret live data streams, offering feedback for quality checks, anomaly detection, and process optimisation. The result is faster turnaround, greater consistency, and sharper operational efficiency.

Simulation is getting smarter. Algorithms learn from experimental data to refine predictive models of particle behaviour. This reduces dependency on physical trials and creates room for virtual testing, which saves time, cost, and materials.

Multimodal analysis is becoming more integrated. AI tools combine insights from imaging, spectroscopy, and thermal analysis to provide a more comprehensive view of particle attributes. CLAIRITY THERMAL, for example, combines hot-stage microscopy with thermal profiling to observe how materials respond over time and temperature.

Larger datasets now drive deeper understanding. Machine learning identifies subtle traits, interaction patterns, and edge behaviours that often remain hidden in traditional workflows. This opens pathways for new formulations, smarter targeting, and material innovation.

These shifts signal more than incremental upgrades. Intelligent feedback, predictive systems, and automated classification are transforming characterization into a decision-making engine. As insight accelerates, industries gain stronger tools to design, monitor, and optimise particles for real-world performance—in pharmaceuticals, materials research, healthcare, and beyond.

Why is particle shape important

Why is particle shape important

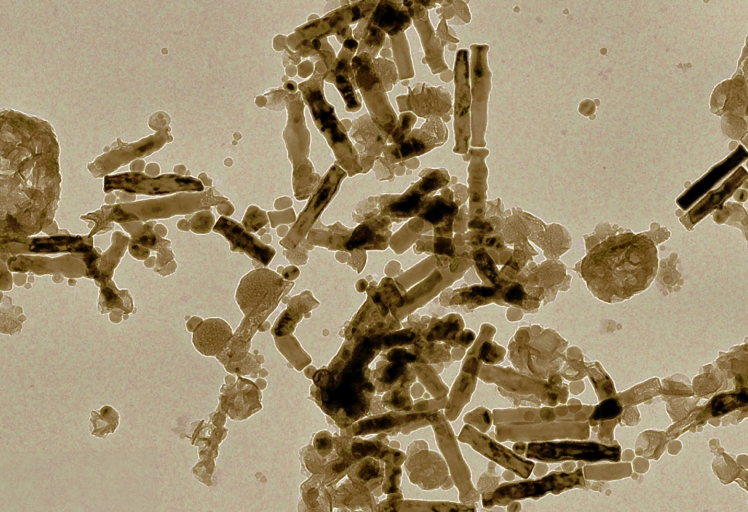

Particle shape directly affects how materials behave in formulation, processing, and delivery. It influences flow characteristics, packing density, stability, and dissolution performance, especially in pharmaceuticals, where morphology significantly affects drug release and absorption rates.

Needle-like or elongated particles often increase surface area, which helps dissolve poorly soluble drugs, but they tend to compromise flow due to higher inter-particle friction. Spherical particles flow more uniformly, making them better suited for tablet compression and consistent dosage forms. Shape also impacts how particles respond to moisture, interact with excipients, and maintain stability over time.

In controlled-release formulations, particle geometry helps modulate the release profile. Parameters such as aspect ratio, circularity, and Feret diameter—measured using SEM, optical microscopy, or image analysis platforms like CLAIRITY—are used to quantify these variations.

Detailed shape data support formulation consistency, minimize batch variability, and provide evidence during regulatory reviews, where particle morphology is treated as a critical quality attribute.

Effects of particle shape and size on drug delivery systems

Effects of particle shape and size on drug delivery systems

Particle shape and size control how a drug behaves during formulation, manufacturing, and delivery. Smaller particles dissolve faster and improve absorption, while their shape influences how they move, settle, or interact within a system.

Spherical particles generally offer better flow and packing, essential for consistent tablet pressing or capsule filling. Elongated or irregular shapes may increase surface area but can lead to processing challenges such as clogging or uneven blends.

In advanced drug delivery systems, such as liposomes or polymeric nanoparticles, morphology significantly affects targeting, uptake, and circulation time. Rod-shaped particles may exhibit better tumor retention, while spherical ones tend to circulate longer in the bloodstream.

Uniformity in particle shape and size reduces variability and enhances formulation stability. Analytical techniques, such as laser diffraction, DLS, SEM, and image-based tools, help quantify these attributes to align performance with regulatory expectations.

Dissolution parametric

Dissolution parametric

Dissolution refers to the rate and extent to which a drug’s active ingredient becomes available for absorption. Microscopic particle analysis reveals how the drug and excipients are distributed, highlighting surface features, particle dispersion, and internal structure.

Combined with image analysis, it helps detect irregularities—such as granule inconsistencies or poor surface exposure—that may influence release patterns. These insights add depth to dissolution testing, offering both structural context and data alignment.

Together, the visual and numeric findings help refine the formulation strategy and maintain consistent performance across batches.

Particle analysis description

Particle analysis description

Particle analysis helps decode how size and shape impact product quality, formulation behavior, and processing reliability. Techniques such as laser diffraction provide insights into bulk distribution, while image-based methods capture finer variations in particle structure.

When consistency depends on the finer details, number-based analysis becomes critical. It identifies subtle shifts in fine particle populations—shifts that influence solubility, flow, dissolution, and even dosage uniformity. These patterns often go unnoticed in volume-based assessments.

At ImageProVision, the focus remains on delivering precise, number-based particle insights tailored to formulation and production requirements. The output supports better material control, sharper quality decisions, and more predictable performance across batches.