Precision imaging across diverse applications

See our Applications- API Particle Characterisation

- Capsule Seam Analysis

- Deformulation Analysis

- Excipient Particle Characterization

- Foreign Matter Inspection (Vial Inspection - Intrinsic & Extrinsic)

- Globule Size Determination in semi-solid dosage forms

- Hot Stage Microscopy

- Microbiology Colony Counting and Gram Staining

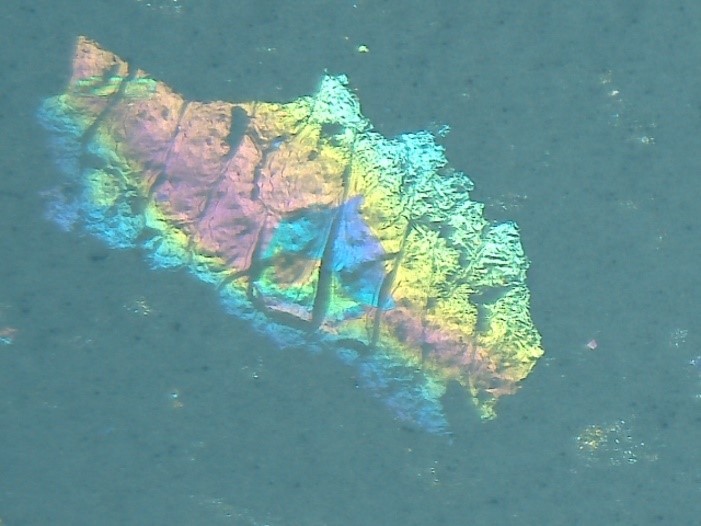

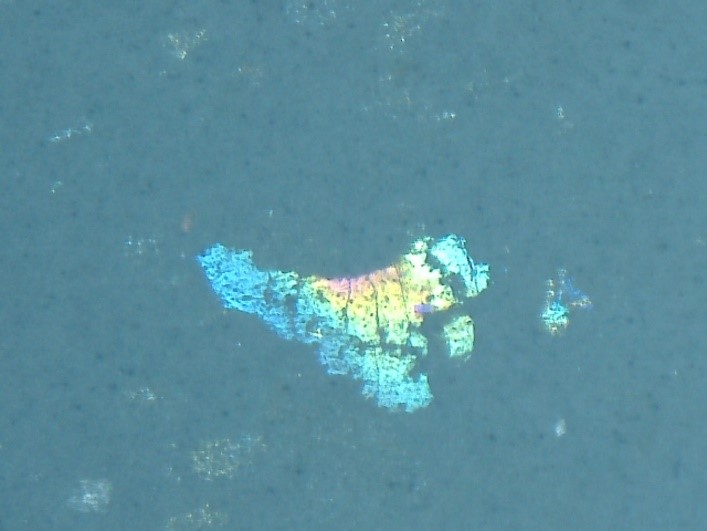

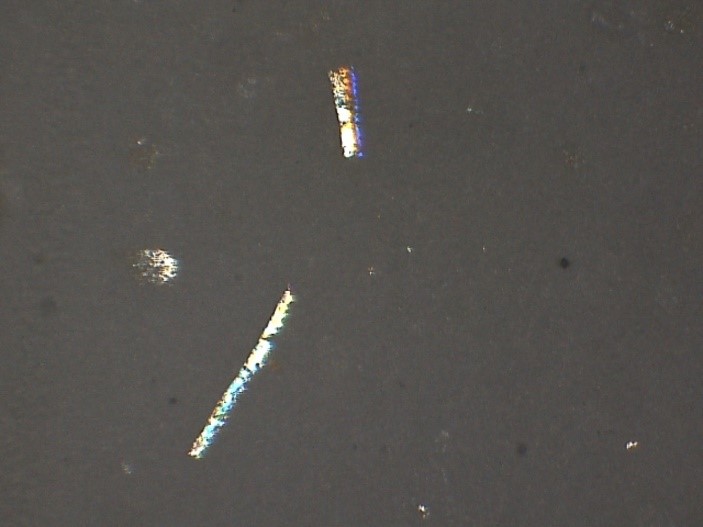

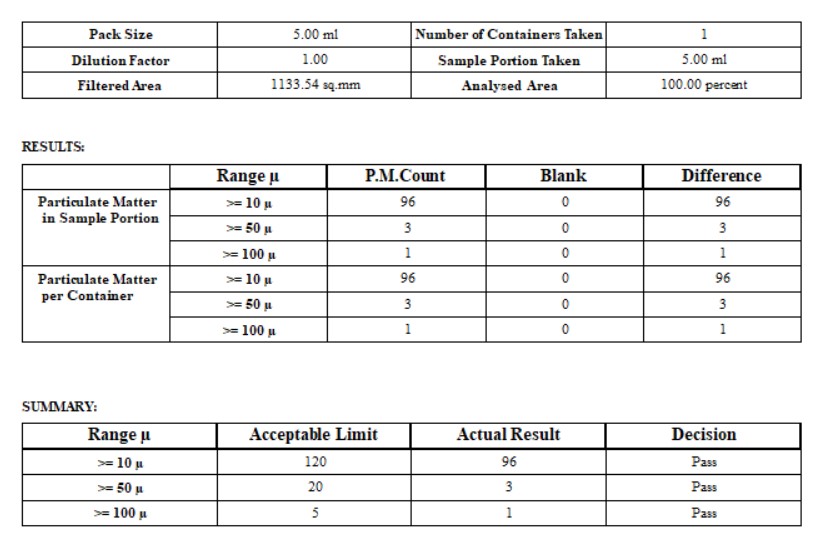

- Particulate Matter Count - Filter Paper Analysis